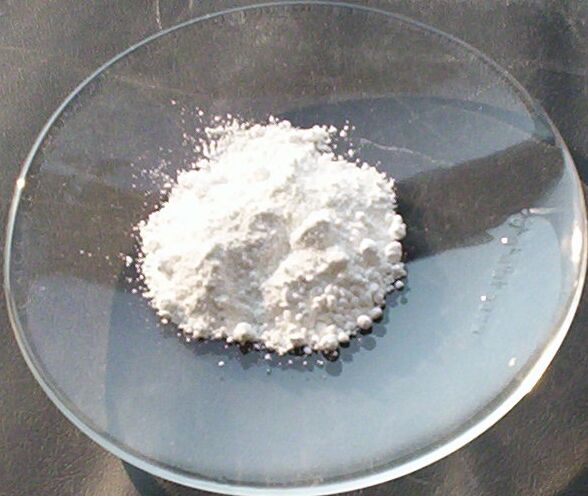

ZnO Additives For Rubber And How It Is Useful During Rubber Vulcanization Process

The rubber industry alone consumes almost 2.5 million tons of fillers along with which they are also responsible for the consumption of around 70% of the entire ZnO additives for rubber. Zinc Oxide is quite a popularly used material in the rubber industry because of its extensive number of benefits.

The Function Of ZnO Additives For Rubber In The Vulcanization Process

The conversion of polymers into tenacious materials with the introduction of the cross-links is a chemical process that is known as the vulcanization process. A renowned example of the vulcanization mechanism is the vulcanization of sulphur where the primary polymers are bridged in a certain way along with the help of sulphur. These bridges or cross links which get formed in each chain of polymer thereby affects the mechanical substance of the polymers because of the process of vulcanization.

Zinc Oxide plays an important role in the composition of rubber. ZnO additives for rubber has gained quite an amount of recognition since it has a number or benefits that tend to be useful in the formulation of rubber and rubber materials. A number of the rubber materials such as the elastomers and amorphous polymers are mixed together with different elements which give rise to a more complex compound. This entire process leads to the fabricating of vulcanized rubber. A number of rubber products that are elastic in nature can be stretched over several times without losing the original form or even getting distorted.

Compared to steel, rubber is less prone to abrasion. This is one of the reasons why rubber is being used instead of steel in a number of industries. Rubber also has the ability to remain the same when it is put inside the solvents and does not have any kind of corrosion that is chemically related. When it comes to commercial rubber materials, natural rubber comprises of polyisopre while the synthetic ones comprises of rubber etylenpropylendien, polybutadien rubber, styrene-propylene rubber and many others.

Synthetic rubbers and rubber materials are produced with the process of condensation of the hydrocarbons that are unsaturated in nature. The commercial synthetic rubbers however are comprised of buna, butyl rubber, neoprene, et cetera.

Zinc Oxide plays quite an important role when it comes to the formulation of rubber materials and rubber itself. It is not only an important accelerator but also an activator in the entire rubber vulcanization process. Due to its ability in ameliorating the thermal properties of any compound it is quite useful in the industry.